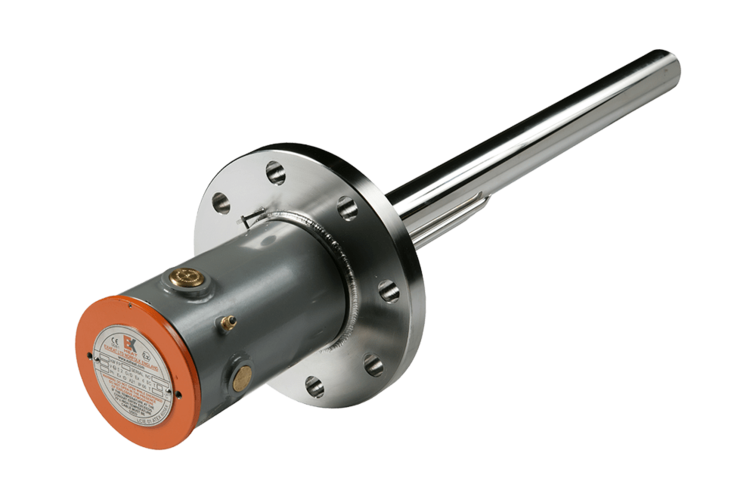

Immersion heaters have an electrical resistant heating element encased in a sheath. When the heating element is activated, it heats its enclosing jacket that heats the sheath, which heats the liquid. Its effectiveness depends on the conductivity of the jacket and sheath.

Direct and indirect immersion heaters use two different methods for heating liquids. A direct immersion heater is inserted directly into the liquid at the top or in a fitting on the side. Its heating element comes in contact with the fluid to be heated. Once positioned, it is turned on and electricity runs through the heating element into the liquid.

An indirect immersion heater is inserted into a pipe with a closed end and immersed in the liquid. The heating element heats the air inside the pipe creating an oven effect that heats the liquid. The advantage and purpose of an indirect immersion heater is that it does not come in direct contact with the fluid, which prevents contamination and corrosion.

The amount of time it takes to heat a material depends on the quantity and power level of the immersion heater. Immersion heaters are designed for specific types of materials to be heated.